MEP Plans in Construction are integral to modern construction processes, but few consider their complexity and importance. These include designing and installing mechanical, electrical and plumbing plans essential for any building project. However, MEP planning for 2025 is all the more important as construction must keep pace with technological advances and sustainability.

In this guide, we explore MEP plans and what they do in construction, leaving you with knowledge of the latest trends and the best practices. Irrespective of the project requirements, whether you are building residential buildings, high-rise towers, or commercial/state building hubs, understanding the MEP plan is necessary for the desired efficiency, compliance and innovation.

What Are MEP Plans: Meaning & Definition?

MEP plans are a detailed plan that describes the design, coordination & execution of vital systems of a building. The ductwork and other mechanical and electrical plans are intertwined these are technical plans required for any construction, wherein the building’s internal functional components are turned into plans.

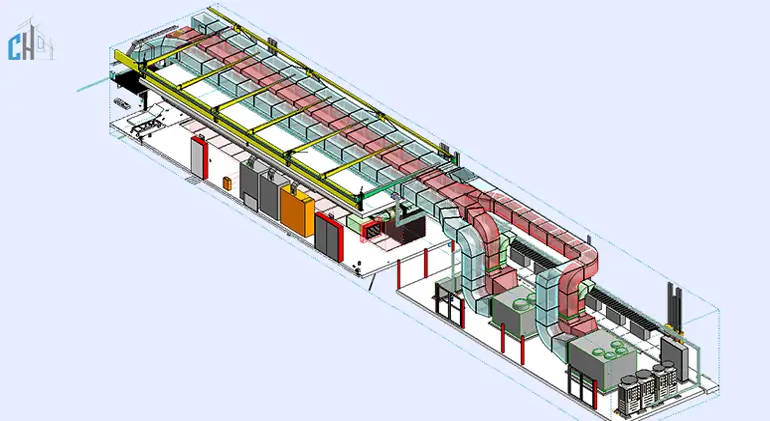

Mechanical (M): Mechanical systems include heating, ventilation, and air conditioning (HVAC) systems. These systems are the ones that serve or directly influence indoor air quality, thermal comfort, and air quality the health of occupants within a building directly hinges upon these systems. MEP (Mechanical, Electrical and Plumbing) plans specify a duct plan, where the HVAC units will go, and so on; it also includes energy management systems per the building design and sustainability principles.

Electrical (E): As the name implies, the electrical part concentrates mainly on power distribution, lighting, communication, electric and security heat distribution systems. Electrical plans include everything from circuit configurations and wiring diagrams to locations of fixtures and outlets. These plans meet the modern demand for smart technologies and energy-efficient solutions to ensure energy is used efficiently without risking anyone involved.

Plumbing (P): Plumbing systems manage water supply lines and waste. Plans for MEP involve networks of piping, areas where waste water will flow, and locations of fixtures. These plans enable compliance with the regulatory standards and ensure sustainable use and management of water pressure within the project site.

What is the Difference Between MEP and MEPFP?

MEP is the abbreviation of Mechanical, Electrical, and Plumbing; when Fire Protection (FP) is included, the scope is further extended, becoming MEPFP. This is an essential inclusion for many modern projects, with safety levels and adherence to fire protection regulations non-negotiables in most cases.

Fire Protection (FP) Fire protection design technologies, such as alarm systems, sprinklers, smoke detectors, and fire extinguishing systems. These systems are vital for protecting the structure of the building and its occupants. Suitable MEPFP plans provide guidelines for the proper and functional positioning of fire protection measures by the fire prevention codes and standards.

Key Differences

MEP Plans:

A mechanical plan and electrical and plumbing plan system, but without elaborate fire protection systems.

MEPFP Plans:

Mechanical engineering plans incorporating fire and protective measures into MEP are essential for total risk management and life safety.

Design Complexity:

MEP Plans:

These are already complicated trades by themselves, but they are coordinated on the MEP over a building layout for mechanical, electrical, and plumbing.

The Role of MEP Plans in Construction

Now that you understand MEP in construction’s meaning, let’s look at how vital these plans are in the broader construction context.

Coordination Between Trades

MEP designs enable the interfacing of the general system and trade. For instance, HVAC ductwork must avoid encroaching on structural elements, beams or other plumbing infrastructures.

Compliance and Safety

One non-negotiable of MEP planning is following the electrical drawings and the building code. With complicated regulations, MEP planning is critical to safety and well-being, especially for the ramifications of the wrong strategy.

Budget and Timeline Management

Without proper MEP designs, construction projects are at risk of inflated budgets and prolonged timelines. Good planning avoids expensive design changes midway through the design.

Sustainability and Energy Efficiency

The efficiency of MEP systems is crucial to meeting sustainability goals by reducing waste and energy use.

Benefits of MEP Plans in Construction Projects

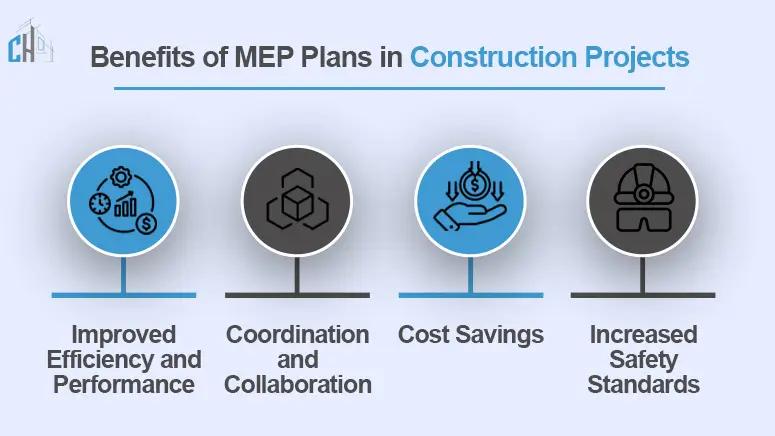

Incorporating MEP plans correctly with well-designed construction plans can be one of the most crucial factors in achieving better workflows and results from construction. Here are some of the key benefits:

Improved Efficiency and Performance

MEP Drafting plans help build practical systems that perform the best in a building structure. Systems like HVAC can be designed so that while providing comfort, the operational costs can also be kept to a minimum with proper planning. With accurate and thoughtful design, potential issues like system overloads can be avoided, thus reducing the frequency of costly repairs and maintenance down the line.

Coordination and Collaboration

By delineating the exact locations of various systems and their spatial qualities, MEP plans allow for efficient coordination between construction teams. Keeping all the teams on the same page eliminates clashes between teams where a plumbing system clashes with ductwork , HVAC ducts with electrical wiring, etc.

Cost Savings

By addressing potential design and installation problems, thorough MEP plans reduce the hidden costs arising during construction. It reduces waste due to excess or short material supply, avoids unnecessary delays, and improves resource utilization through clearer architecture software development specifications. Moreover, projects can stay on cost by optimizing installations and limiting design adjustments.

Increased Safety Standards

Following MEP plans, the safety levels ensured in construction projects have skyrocketed. One major aspect of MEP planning is compliance with local building codes and safety regulations. Detailed MEP strategies ensure that constructions minimize risks, such as electrical hazards and improper plumbing component setups, that might endanger a building’s functionality or its occupants’ safety and health.

Best Practices for Effective MEP Planning

Proper MEP planning increases efficiency, enhances safety, and reduces costs. Here’s how to achieve it:

Collaboration and Communication

Collaboration between architects, engineers, and contractors from the initial stages of a project is crucial. Regular meetings can prevent clashes between systems later on.

Utilize Advanced Technology

BIM (Building Information Modeling): A paradigm shift for MEP designs, enabling accurate information generation containing 3D models and enhanced visualization.

CAD Software: The design process starts in CAD with basic shapes and structures and then moves into powerful modelling to eliminate detailed drawing errors.

Adhering to Standards and Codes

Industry-specific regulations such as ASHRAE (HVAC standards), NEC (electrical standards), and local building codes sustainable building, should always be followed.

Trends in MEP Planning for 2025

MEP in building construction is a relatively fast-evolving field, especially with recent technologies and sustainability targets. What to expect in 2025: Here they are.

Sustainability and Energy Efficiency

Designing for green buildings is now mandatory, and net-zero energy buildings are becoming the new norm. More advanced solar energy systems, as well as geothermal technologies, will continue to expand.

Smart Building Technologies

IoT (Internet of Things) integration, along with predictive maintenance systems, ensures that they are continuously monitored to address any problems before they get out of hand.

Digitalization and Automation

- AI Design Tools: Create faster, more accurate MEP plans.

Digital Twins: These are simulations that provide real-time monitoring of MEP performance.

Why Choose Chudasama Outsourcing Company for MEP Design Plans?

Looking for reliable MEP design plans? Here’s why our company is the perfect choice for your project.

Expertise and Experience

Over the years, Chudasama Outsourcing, a leading MEP BIM Modeling Services Company in USA has created a solid reputation for fine MEP designs for almost every industry. With extensive experience in the electrical, plumbing and mechanical system professions, their crew of experts assures top-of-the-line technical assistance for your project.

Advanced Technological Integration

Using the latest technologies, such as BIM and CAD software, Chudasama Outsourcing designs MEP systems with exactness and effectiveness. This technology gives the project delivery a collaborative environment, fewer errors, and a more effective overall outcome.

Commitment to Sustainability

Chudasama Outsourcing is focused on encouraging environmental sustainability through MEP designs. They combine energy-efficient solutions and sustainable practices that enable projects to comply with green building standards and contribute to a healthier environment.

Cost-Effective Solutions

Chudasama Outsourcing can provide clients with a low-cost solution for MEP design without compromising on quality. Willing to own the project and provide its completion at reasonable rates

Because it provides a way for projects to be delivered on time and within budget when employing management practices, chudasama outsourcing is based on less waste and more optimized resources, which has proven to be less costly for the clients.

Streamlined Processes

Poshmark employs an efficient workflow that combines productivity and quality. Focusing on meticulous planning and implementation, they minimize wasteful delays and ensure smooth incorporation of MEP systems in the overall construction industry project.

Extensive Project Portfolio

Chudasama Outsourcing has a wealth of experience across multiple sectors, such as residential, commercial, industrial, and institutional. The wide range presented in this portfolio illustrates their capacity to adapt to different project needs and provide pragmatic MEP solutions that help clients achieve goals and expectations as efficiently as possible.

Client-Centric Approach

Chudasama Outsourcing offers MEP BIM modeling services that keep customer satisfaction at the heart. They keep a close line of communication with their clients, clearing out any doubts and issues arising during the project. This guarantees that clients are engaged and kept in the loop at each process stage, resulting in successful projects and solid relationships.

Hence, selecting an MEP design plan creates a strategic advantage when Chudasama Outsourcing Company is paired through expert knowledge, innovative technology, and optimized solutions to achieve sustainable quality popular in shape for your construction plans.

Move Forward With Stronger MEP Plans

Gone are the days of MEP being merely a static piece of construction; today, MEP planning is the cornerstone of building modern, effective, sustainable structures that will last well into the future. Professionals are upping their standards for what MEP systems can do, and that starts with prioritizing sustainability, collaboration, and advanced technology.

If your project requires professional MEP design, we can help you to start it right. By following a careful plan, you can optimize your systems and efficiency. And we are focused on making projects like yours successful in 2025 and beyond.