The guide to architectural millwork shop drawing services advantages that are associated with the construction area and include enhanced precision, as well as the options of customization and improved efficiency. Study how these services contribute to improving global construction initiatives to be more innovative and successful.

In the intricately woven process of project construction, accuracy is essential. In the millwork shop drawings, we start seeing one of the hidden characters, which has affected the architectural design and synergy creation of the on-the-ground implementation.

This all-inclusive guide equips architects and construction companies with the information they need to utilize millwork shop drawing regulations, including the understanding of the manufacturing process and how to select the right service and incorporate the latest technologies.

What Are Millwork Shop Drawings?

Millwork shop drawings are precise technical illustrations which form the basis for all the custom architectural millwork craft in terms of cabinetry, moldings, trims, doors, and windows. Being an inseparable part of the construction process, drawings offer the exactness as the blueprint for the fabricators to build the sheet models.

Millwork panel shop drawings provide a linkage between the design plans and the final product specification, thereby guaranteeing that everything sticks to the design.

How Are Millwork Shop Drawings Created?

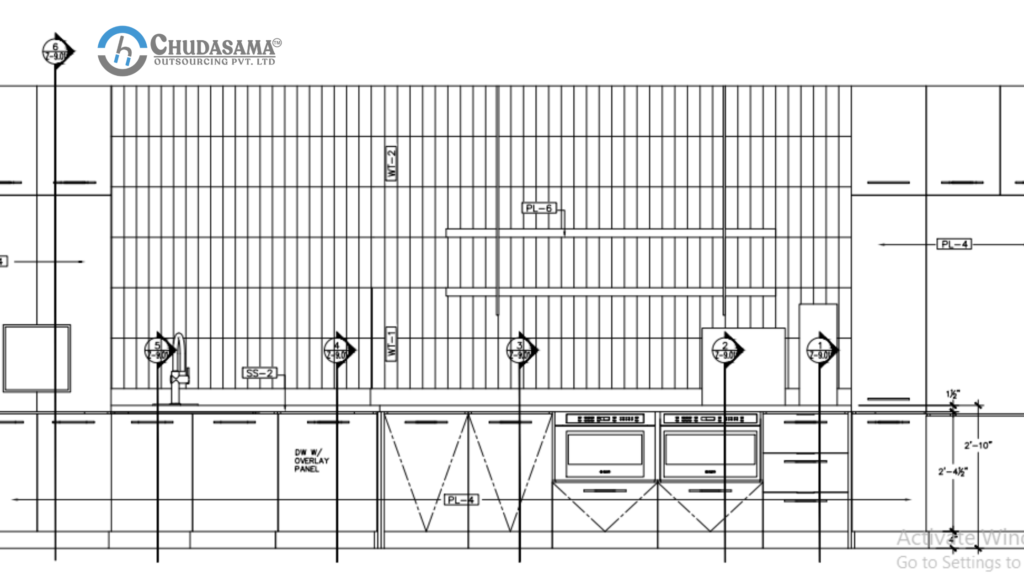

The drawings for the millwork shop are traditionally created by CAD drafter designers or digital illustrators who have experience using CAD (Computer-Aided Design) software. They cooperate with architects, designers, and contractors to provide details of the project’s performance specifications and engineering solutions to the unique needs of the project. Through the software they use, they rigorously carry out the design drawing into a detailed, precise, and technical layout with all designed standards and code applied.

Shop drawings for millwork, just like other kinds, are also schemes, but they are much more illustrative, with detailed descriptions about how to make and install millwork and cabinetry for interior architectural works.

This artwork is, in essence, the pathway through the maze leading from a designer’s idea of the ideal wooden furniture to the furniture actually seen around. Their precision and accuracy are beyond amazing as they are the basis of documentation that specifies the way in which beautiful, customize, and often complex woodwork in the design could made.

They are the amalgamation of two basic elements of any inside spatial planning process, starting from the executive offices to single-person coffee shops and places in between. The convenience and practicality of shop drawings, which are so instrumental to the professionalism of carpenters and installers, appeal to every facet of production.

Shop drawings can contain precise proportions and other material specifications, assembly methods, and installation details. Thus, they safeguard against expensive mistakes and time delays during the construction process. Designing allows them to communicate what they have in mind as architects with the engraving of plans as a consequence.

The Benefits of Using Architectural Millwork Shop Drawings Services

Which way to give a millwork shop drawing a rise into your project is a business decision that you make.

Cost Savings

After all mixed up units of measurement, materials, and design language, the possibility of online the quality and accuracy of the job is low. This is implicative of rework, material wastage, and project delays. Experts in the field of building design assert that this might reduce construction costs by up to 10 dollars, while one dollar is spent on shop drawings.

Through the shop drawings, the margin for error becomes minimal as the has created a visual and technical manual for the carpenters, installers and among others.

Improved Accuracy

The millwork shop work is custom-made for each project to fulfil all the project-specific characterization prompts from spaces. The level of precision illustrated in these drawings leads the way to a high-quality final product with almost no requirement for onsite modifications.

Enhanced Project Efficiency

Minimizing resources, such as energy and water, is an imperative and strategic aspect of project execution. Therefore, shop drawings ensure that the analysis and remedy of design issues happen before construction begins, thereby increasing the construction length. What doesn’t come to mean are fewer changes and a running, sequential flow of designs to installation.

Understanding the Creation Process

A given shop drawing creation process is strictly a stage-by-stage one, and the stages themselves have their specifics and an array of demands.

Initial Consultation

In the initial phase, the shop drawing team interfaces with the architects, interior designers, and construction managers, who are the project’s identified stakeholders. Here, I will describe carefully and complete the goals and objectives of the project. This line aims to determine whether the drawings are accurate per the overall vision of the project.

Field Measurement

Reliable field measurements are the base for shop drawings and millwork. Visiting the construction site in person, the shop drawing team gathers detailed dimensions — reflecting the actual spacing of the location — which account for all the possible deviations from the existing plans.

Drafting and Design

Sketching presents the stage where the measurements and design concepts are all laid out. By employing a specific program, the drafters prepare 2D and even 3D renditions depicting the millwork detailing, paying attention to issues like material choice and assembly methods.

Client Review and Approval

Furthermore, the process of review must be transparent and framed by cooperation. A client review is realizing for the initial shop drawing performance and accuracy. Feedback is guiding in, at which stage we make further improvements to the artwork till you approve it.

The Integration of Technology in Millwork Shop Drawings

Technology has been a game changer when it comes to millwork design and fabrication, dropping the error rate enormously.

Software and Tools

Industry-standard state-of-the-art design software such as AutoCAD, Revit, and SolidWorks being instrumental in shop drawings with all the fine details is now the norm. These cloud-based systems provide diverse tool performance and enable easy collaboration among different stakeholders.

Impact on Project Outcomes

The digital era has boosted the world of designing through modeling 3D formats that give clients a realistic view of the final outcome, 360 degrees, which lets everyone walk through the project before building it. These enhancements actually make a blanket impact on project success by speeding up communication, minimizing errors, and facilitating the construction process.

Choosing the Right Millwork Shop Drawings and Drafting Service

Selecting a proficient millwork shop drawings service is an important factor in ensuring accuracy and high-quality projects.

Deciding on the appropriate service supplier is a crucial issue and requires careful judgment and assessment, as it will affect your project’s success significantly.

Factors to Consider

When evaluating potential shop drawing partners, consider their experience, expertise, and portfolio. Look for a service provider who understands the complexities of millwork design and has a history of delivering accurate and timely drawings.

Case Studies

Through case studies, the level of work that has been done and the results the service has attained may be grasped. They could remind students how these shop drawings actually materialized the final works.

Chudasama Outsourcing, a multi-national company that provides Millwork Shop drawing services, takes pride in the products and services that it provides, which are of high quality and perfect. Consistent, high-quality service from a company that already has an establish history of getting good results is guarantee.

Conclusion

The key to the successful implementation of millwork shop drawings is not just a small task on the way to the perfect completion of the project—it is an essential factor of success that factually influences the results. As you outline your building schematic, do not forget that these drawings supply a lot of knowledge not only about aesthetics but also about structural needs.

Create a setting where everything, starting from the minute detail until the climactic main idea, is brilliantly planned, executed, and exhibited to the admiration of every attendee whose tastes are made complete by the combination of the latest technology and the expertise of humans.

Concerning the occasional lack of precision and interpretation during the manual process, we provide you with the best way to make our company a part of your next project. The best deserves the best service; that is why you experience excellence with us.